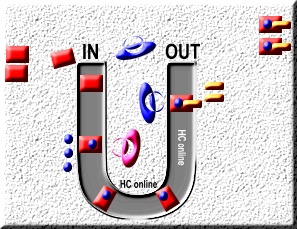

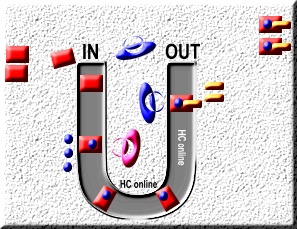

The layout of workcells in a U shape has several advantages:

The IN and OUT are close, allowing visual control and management, according to the production takt,

a single person can handle both the cell input feeding and output

The shortening of distances allow sharing of work, as well as reduction of transportation waste

These layouts provide convenient foundation for one piece flow

Communication among team mates in the cell is easier

The work is done inside the U, supplies remain outside

Usually machines and tables are on rollers (if possible) for quick reconfiguration

The floor space is generaly fewer with a U cell than stretched line

(including inventories and supplies), walk distances are also reduced, as they are Muda (waste).

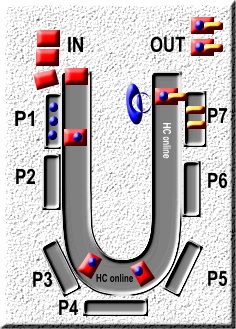

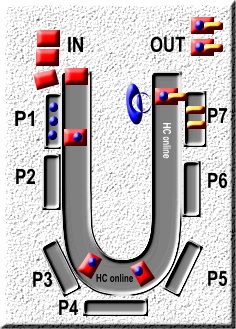

Some tasks can be handled by few operators, going from one workstation to the next in the cell.

According to production takt and job contents, even a single person can manage all the work in the cell.

The cell can be made flexible if some station are dedicated to specific models or options:

Station vs models Matrix

| Standard | Deluxe |

| P1 | Yes | Yes |

| P2 | No | Yes |

| P3 | Y | Y, 2 per side |

| P4 | Y, Silver | Y, Gold |

| P5 | N | Y |

| P6 | Export only | No |

| P7 | Y | Y |

|

|

Author Chris HOHMANN is

manager and consultant in an international consulting firm.

Contact Contact

|

CHAKU-CHAKU

Chaku-Chaku is a takt flow job consisting in loading/unloading parts from one machine to the next

according to a sequence the operator walks in the cell.

|

|