Lean Engineering |

Last update: Fabruary 16th, 2010

|

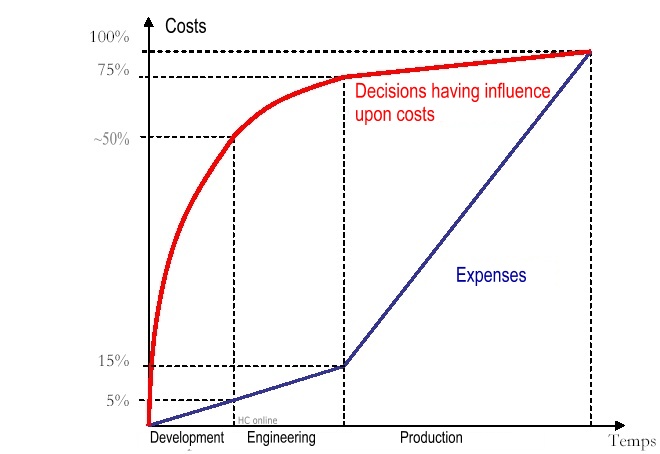

Efficiency limited by initial choices

Its a common experience made while looking for improvement opportunities on shop floor, the first validated actions are those easy to carry out and giving the most interesting return on investment (A), the low hanging fruits. The second set of actions (B) tries to built further upon the success factors seen in first phase, mainly based on continuous improvement (Kaizen). Yet those approaches despite their many benefits (motivation, training and operative results), will be limited by their return on investment (C). On one side, chasing the last remaining improvement would require huge investments compared to gains, on the other side performances are limited by initial choices. ExampleOne significant example is the shop layout of some old automotive plants in "old Europe". Lessons learned since Lean deployment benefit more the green field plants in emerging countries than the old ones,

giving them even more competitive advantage. Product and process costs as well as future performances are limited by initial choices

In the same way, future performance is for the most fixed by the same initial choices. Later improvement suggestion cannot challenge these choices and have to be limited to restricted domaines or minor trimmings. Therefore, the opportunities to influence the (initial) choices for less expensive solutions or solutions carrying better performance potentials for future are limited to the early development phases.

Otherwise, as the development process nears production launch, the cost of modifications becomes prohibitive.

|

Other readings:

|

This page was brought to you by ©hris HOHMANN - http://chohmann.free.fr/

| |||||||||||||||||||||||||||

Development and engineering phase consume about 15% of total costs but decide 75% of these costs.

Development and engineering phase consume about 15% of total costs but decide 75% of these costs.