Benefits of batch size reduction |

|

Last update: December 31st, 2008

|

Benefits of batch size reductionIn the previous page we explained the meaning of production batch. Now we introduce the transfer batch. Transfer batch and production batch

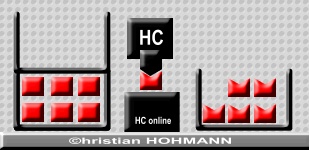

Keeping previous example, we introduce a change in parts storage. Production batch (still 12 parts) is stored in two smaller containers holding six parts only, in front of the machine. Like before, an empty container is set after the machine to collect finished parts. At production start, the first part is set onto the machine, while 11 others wait for their turn. Just like before, 11 parts will dwell while one is processed. Once the sixth is done, the first container in front of the machine is empty, while the one after the machine is filled with the sixth part.

As this container holding finished parts is full, it can be moved to next operation. This transfer batch size is six. The now emptied container in front of the machine is to replace the one moved. Part number seven is processed.

A change happened. From now on, only five parts will remain dwelling while one is being processed.

Once the twelfth part is done, the whole production batch is completly processed. The second container holding six parts can be moved on to next operation. Production batch is still 12 parts. Total processing time for 12 parts remains unchanged, yet the transfer happens every six parts. Introducing transfer batches smaller than production batch allows to feed next operation earlier and have fewer parts dwelling.

|

| This page is brought to you by ©hris HOHMANN -

http://chohmann.free.fr/

| ||||||||||||||||||||||||||

Read next chapter

Read next chapter