Heijunka, production levelling

|

|

Last update: March 3rd, 2010

|

Production levelling, an example (Part 2)To improve the time to market and gain flexibility, it is necessary to split the batches. It means find a compromise between minimum batch size, costs on one side and the efforts for additional changeovers and economies of scale through big batches, as well as to work with constant rhythm in a standardized maner. Find a patternComming back to the data of history of orders, try to find a basic pattern fitting our criteria.

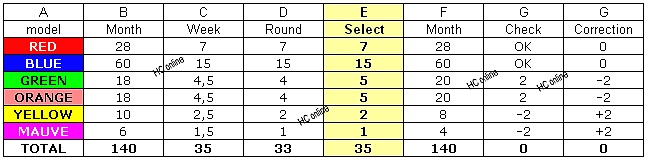

The chosen time span is the week. In the table below, the monthly requirements are in column B. The weekly average requirement is in (C). As we can only manufacture complete and discrete units, there is a need for rounding in (D). Rounding give a excess time, for which we need to choose how to use, e.g. what product should be produced "in excess" (E). The column E becomes the weekly production plan.

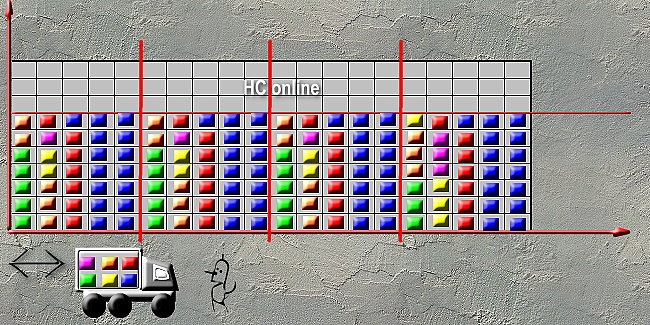

In column F the new monthly result if we apply our pattern 4 time, and for which we check the consistency with requirement (B), in column G. Adjustment between excess and shortage is done in the fourth week. The resulting visual plan is shown below. Each week the same basic pattern is repeated (colonne E) and ajustments done during last week.

The table above shows the usable hours in each day (columns)

for the whole month of 20 days. PerformanceOur client whishing a unit of each product can be delivered the second day.

Performance measured by the ratio usable time / total time; 6 / 2 x 7 = 43%Progression compared to initial situation (delivery in 20 days, ratio ut/tt 4%) : +90%

|

| Return to principle

This page was brought to you by ©hris HOHMANN - http://chohmann.free.fr/

| ||||||||||||||||||||||||||||||||||||||||

Scheduling with Heijunka box

Scheduling with Heijunka box