Heijunka, production levelling

|

|

Last update: March 3rd, 2010

|

Production levelling, an exampleA workshops works 7 hours a day, 5 days a week, 20 days per month, manufacturing a product in one hour, product available in six colors. The market average monthly demand has following distribution:

The market demand can be managed, as our load-capacity check

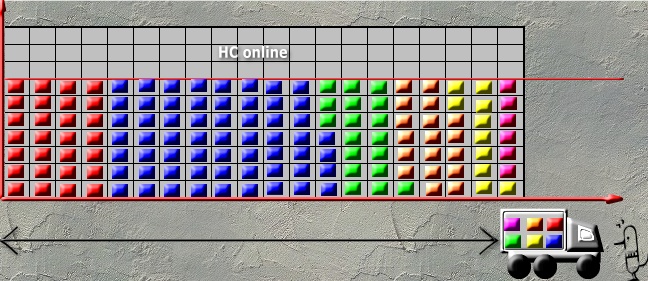

confirmes. First approach, "traditional planning"A relatively common approach in mass production is to optimize the usage of resources, seek economies

of scale with huge production batches, hence minimizing the time spent for changeovers.

Another common practice is to start the month with the longest series, letting the shorter ones for the end of the month.

The table hereunder shows the usable hours in each day (columns)

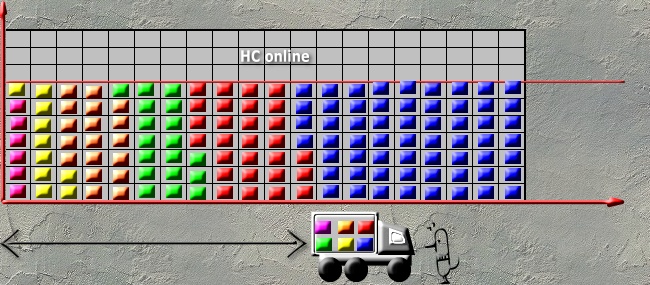

for the whole month of 20 days. In such a case, the client ordering a unit of each type, 6 in total, and ordering the first day of the month, has to wait the month's end (20 working days) before being delivered. All that waiting for an accumulated production time of 6 hours. The ratio usable time / total time is: 6 / 20 x 7 = 4%A first improvementA first improvement could be reversing the order of series; starting the month with shorter ones.

The client can then be delivered within 12 days (8 if one Red unit can be shipped as soon as

manufactured), which is already a significant gain.

The ratio usable time / total time is; 6 / 12 x 7 = 7% Progress +43%To sustain it, the next month should not restart with a long Blue serie to save a changeover, otherwise the same client, with the same order will see his service rate fall again.

|

| Return to principle

This page was brought to you by ©hris HOHMANN - http://chohmann.free.fr/

| ||||||||||||||||||||||||||||||||||||||||

Heijunka through an example, continued

Heijunka through an example, continued