Lean Engineering |

|

Last update: December 26th, 2008

|

From cure to lean conceptionLean deployement is most often experienced as a response to malfunctions or a way to improve performance in existing systems, so rather in a "firefighting" perspective. However, lean should also be considered from the very early design stage of products or services. Scheduled at latest

The result are a growing waste of energy and soaring costs and expenditures, increasing to a state of panic as important milestones are to be met. Under the generic term "expenditure", it should be understood:

With much effort, the deliverables expected at To are partially rendered at T1. Delays and inefficiencies are coped in successive waves, but still adding additional costs. Best practice: avoid wastes and mitigate risks

It is necessary to estimate every risk factor jeopardizing the project and mitigate the risks by putting in place preventive measures like capacity and capability audits, alternative sourcing, and so on. Doing that, the design costs are increasing according to plan, and then decrease after launch, as only little work for remaining corrective actions is necessary, if any. These precautions also apply to subcontractors and suppliers involved upstream. Lean EngineeringThe choice of production means for latter launch phase is often "default based", reusing available means or doing as "usual". Going this way can saturate the installed capacity and lead to decide new investissements, regardless to other alternatives.

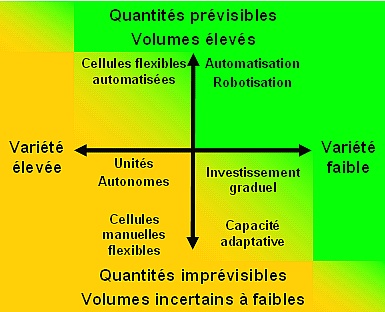

The matrix (right) is usued to analyse the needs for production means according to two parameters;

If quantities are certain and variability low (upper right), it is meaningful to invest in automation. Conversely, if quantities are few and product range wide (lower left), it is better to use flexible low cost means, easy to install and convert. The right policy for lower right quadrant is to use the narrow range of part numbers and wait for forecasts or firm orders before activation or investments in additionnal means. The upper left quadrant, showing a combination of high variety and volumes, calls for fexible automatisation.

|

|

This page was brought to you by ©hris HOHMANN - http://chohmann.free.fr/

| ||||||||||||||||||||||||||