|

Quality flaw costs |

|

Last update: May 11th, 2010

|

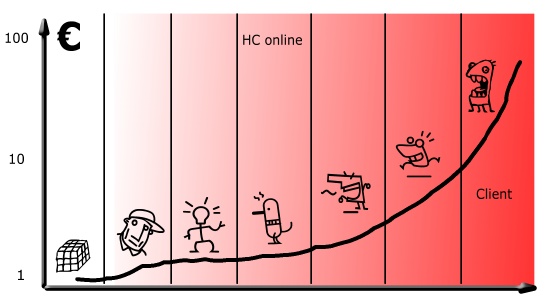

The costs of quality flaws vary according to the tardiness of their discoveryOne of the obvious things it it useful to recal is that the later a quality flaw (defect) is discovert,

the higher its cost. Indeed, the streamline of production or transformation process is a value adding process which increases

raw material or product value at each step.  If defect detection occurs once the product left the plant, the costs will raise in

accordance to the efforts spent to locate, return or replace it.

|

| This page was brought to you by ©hris HOHMANN - http://chohmann.free.fr/

| ||||||||||||||||||||||||||